Automated Order Processing That Scales Your Business

Discuss with AI

Get instant insights and ask questions about this topic with AI assistants.

💡 Pro tip: All options include context about this blog post. Feel free to modify the prompt to ask more specific questions!

Automated order processing is simply using technology to handle the entire journey of an order, from the second a customer hits 'buy' all the way to the delivery notification, without anyone needing to lift a finger. Think of it as upgrading from a single person trying to juggle every task to a perfectly coordinated, lightning-fast assembly line. This digital workflow gets rid of all those repetitive, soul-crushing tasks, paving the way for your business to grow without hitting a ceiling.

Let’s get practical. Imagine you're running a business where orders are managed manually. It probably feels a bit like being a short-order cook during the lunch rush—by yourself. You're taking orders by phone, scribbling them down, trying to cook everything, plate it, and process the payments all at once. It's pure chaos. It’s not just stressful; it’s a recipe for disaster. An order gets misplaced, a custom request is overlooked, or the wrong item gets shipped. This is the daily reality for countless businesses still stuck managing sales with a patchwork of spreadsheets and email threads.

Now, picture that same kitchen with a serious upgrade. Orders from every channel—your website, third-party marketplaces, in-person sales—all flow into one unified system. Payments get verified on the spot. The warehouse gets crystal-clear instructions. The moment the package is ready to go, the customer gets a notification. That’s the magic of automated order processing. It’s not about one single piece of software; it's about an entire interconnected ecosystem built for speed and precision.

This system essentially becomes the central nervous system for your entire sales operation. It connects all the dots in the fulfillment process, making sure every step is triggered automatically and in the right order. The whole point is to create a hands-off workflow that's far faster and more dependable than any human-powered process could ever be.

So, what does this system actually do? Without any manual prodding, it handles a few critical jobs that used to eat up hours of your day.

Here are its primary functions:

- Capturing Orders: It instantly grabs order data from all your sales channels, whether that's your Shopify store, an Amazon listing, or a direct B2B portal. No more manual data entry.

- Verifying Payments: The system confirms the transaction is legit in a split second, flagging any suspicious payments for a quick human review.

- Checking Inventory: It pings your inventory system in real-time to make sure you actually have the product on the shelf before the order is confirmed.

- Routing to Fulfillment: It intelligently directs the order to the best warehouse or 3PL based on rules you set, like customer location or current stock levels.

- Keeping Customers Informed: Automated emails or texts are sent out for order confirmations, shipping alerts, and delivery updates, keeping customers happy and in the loop.

This kind of automation, often driven by technology like robotic process automation (RPA), delivers a pretty incredible return. In fact, companies can see an ROI from 30% all the way up to 200% in the first year alone. But here's the catch: getting it right is crucial. With nearly 70% of digital transformation projects failing to hit their goals, a thoughtful implementation is non-negotiable. You can discover more insights about these automation statistics to understand the challenges and the massive potential.

Don't think of an automated order system as just one piece of software. It’s more like a finely tuned engine, with a bunch of interconnected parts all humming along in perfect sync. Each component has a specific job to do, and when they all work together, they create a seamless journey from the moment a customer clicks "buy" to the package landing on their doorstep.

Let's pop the hood and take a look at the critical components that make this whole modern workflow tick.

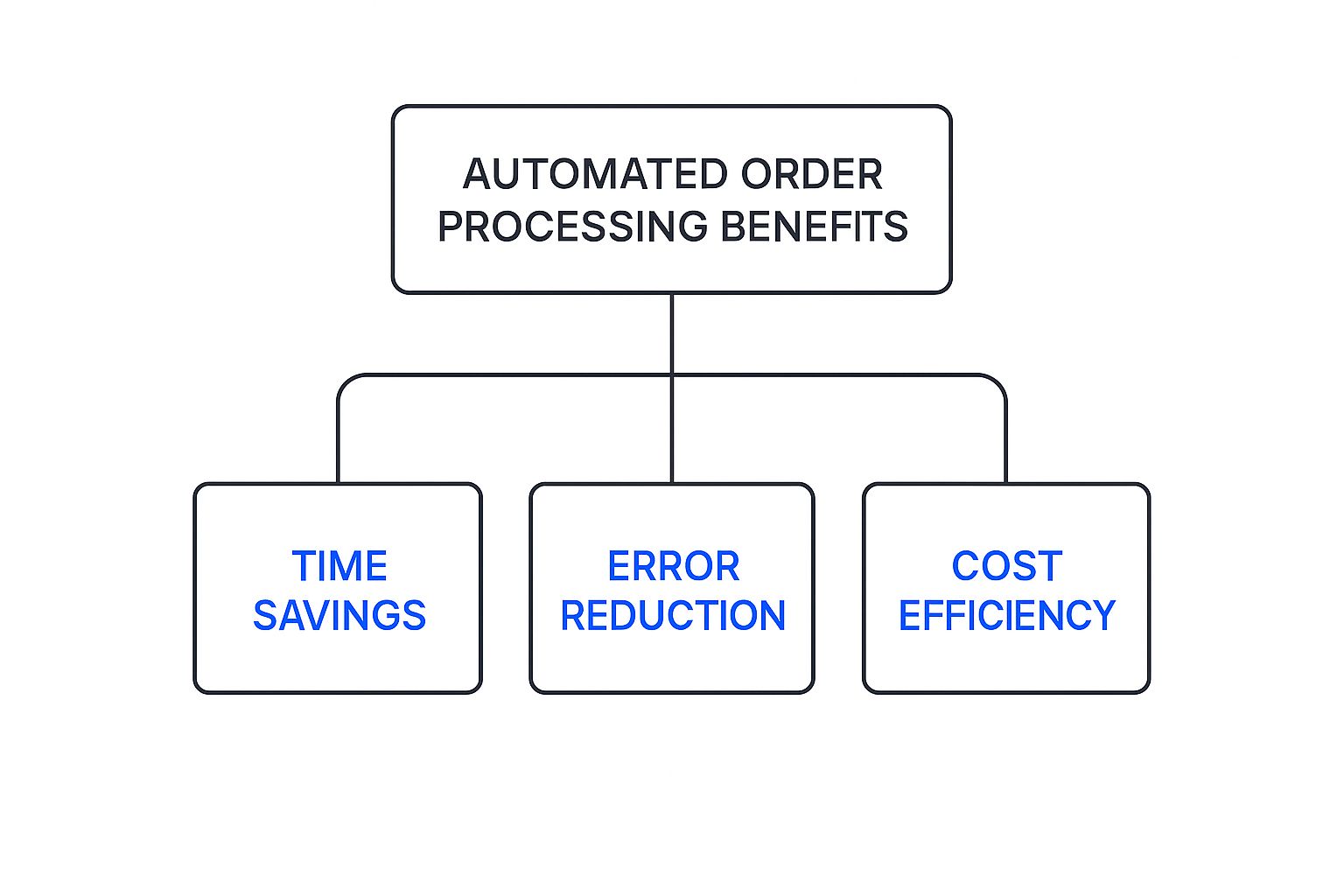

As you can see, a well-oiled automated system directly leads to saving time, cutting down on mistakes, and making your entire operation more cost-effective.

At the very heart of any automated order processing system is the centralized hub. This is the command center, the brain of the operation. It pulls in all your orders from every single sales channel—your Shopify store, your Amazon listings, social media shops, B2B portals, you name it—and puts them all into one unified dashboard.

Without this, you're stuck logging into each platform one by one, downloading spreadsheets, and trying to piece everything together. The hub gets rid of that chaos, making sure no order ever slips through the cracks and giving you a single, reliable view of all your sales. It's the difference between having one organized inbox versus a desk covered in scattered sticky notes.

Okay, so an order comes in. What happens next? The system instantly talks to your inventory. Real-time inventory sync is the magic that keeps your stock levels perfectly accurate across every single place you sell, both online and in physical locations.

This is a non-negotiable component. It prevents that dreaded "overselling" nightmare where a customer pays for an item that’s already gone. The moment a sale happens, inventory counts are adjusted automatically, which drastically reduces backorders and keeps customers happy. If you have multiple warehouses, this sync is what tells the system to route the order to a location that actually has the product on the shelf.

Protecting your revenue is just as important as making it. That’s where automated payment verification and fraud screening come in. A secure payment gateway is built right into the system to handle every transaction instantly and safely.

But a modern system does more than just process a payment—it actively protects it. Automated rules screen for fraud by looking at transaction details, flagging high-risk orders, and verifying customer info, all in the blink of an eye.

This layer of automated security is your first line of defense against costly chargebacks and fraudulent purchases, protecting your bottom line without ever slowing down the checkout experience for legitimate customers.

So, how does the system know which warehouse or fulfillment partner should handle the order? That’s the job of smart fulfillment routing. Think of it as the system’s built-in GPS. It uses logic to intelligently send an order to the best possible location for fulfillment.

This routing isn't just random; it's based on a set of rules that you get to define. These often include:

- Customer Location: Sending the order from the warehouse closest to the customer to slash shipping times and costs.

- Stock Availability: Directing the order to the facility that has enough stock to fulfill the entire order at once.

- Carrier Rates: Choosing a location that can ship to the destination using the most cost-effective carrier options.

Once the order is picked and packed, it’s time to ship. Integrated shipping automation connects your system directly with carriers like FedEx, UPS, or USPS. This handshake allows the system to instantly generate shipping labels, calculate the correct postage, and create tracking numbers without anyone having to lift a finger.

This integration is a massive time-saver. No more tedious copy-and-pasting of addresses from one system to another. It also cuts down on shipping errors, since the label information is pulled directly and accurately from the original order data.

Finally, a truly great automated system keeps your customers in the loop. This is all handled through proactive customer communication workflows. The system automatically triggers and sends out emails or text messages for key updates in the order's journey.

These automated touchpoints are essential for building trust:

- Order Confirmation: Sent right after purchase to let the customer know their order is in the system.

- Shipping Notification: Fired off the second a shipping label is created, complete with a tracking number.

- Delivery Update: A final ping to confirm the package has been safely delivered.

This constant, helpful communication not only builds customer confidence but also dramatically cuts down on "Where is my order?" calls and emails. That frees up your support team to handle more complex issues that actually require a human touch.

Let's move past the technical jargon and get to the heart of the matter: what does automated order processing really do for your business? This isn't just about shaving a few seconds off your workflow. It's about building a fundamentally stronger, more agile, and more profitable company.

The effects are far-reaching, touching everything from the person packing boxes in your warehouse to your customer service team and even your marketing plans. By getting rid of the manual clogs in your system, you open the door to a level of performance that was simply out of reach before.

Every time a person types an address or an SKU, there's a chance for a mistake. It’s just human nature. A single typo in a postcode can send a package on a wild goose chase, leaving you with a frustrated customer and the bill for reshipment. An incorrect product code? Now you’re dealing with a return, an exchange, and a hit to your brand's reputation.

Automation virtually erases this risk. The system pulls order details directly from the customer’s checkout, ensuring the information that lands in your warehouse is exactly what the customer provided. This precision drastically cuts down on errors in shipping addresses, product picking, and packing lists. To see how deep this goes, consider the advantages of automatic labelling, which further protects the final, crucial stages of fulfillment from manual slip-ups.

In e-commerce today, speed isn't a luxury; it's a weapon. Manual processing is the ultimate speed bump. A person can only key in and verify so many orders per hour, and that bottleneck becomes a serious anchor on your growth.

An automated system, on the other hand, can process hundreds or even thousands of orders in the time it takes a human to handle a handful. This means orders are validated and sent to the warehouse floor almost instantly. The gap between a customer's click and their package shipping out shrinks dramatically, leading to the fast delivery times that build loyalty.

Today’s shoppers expect a smooth, transparent journey. They want an immediate order confirmation, up-to-the-minute tracking, and clear communication if something changes. Trying to deliver this level of personal attention manually is a recipe for burnout and failure.

Automated order processing makes this high-touch service your baseline. The system fires off confirmations, shipping alerts, and delivery updates without anyone lifting a finger, keeping your customers in the loop and feeling confident.

This proactive communication does more than just build trust. It dramatically cuts down on the constant "Where is my order?" emails, freeing up your support staff to solve real problems. As we explore in our guide on customer service automation, this shift allows agents to focus on high-value interactions that truly make a difference.

What happens when your brand has a viral moment or a Black Friday sale shatters your projections? For a business running on manual processes, a sudden flood of orders can be a nightmare. It means scrambling to hire temps, navigating total chaos in the warehouse, and making inevitable mistakes that disappoint customers.

With an automated workflow, you can handle those massive sales spikes without breaking a sweat. The system scales up instantly, processing 1,000 orders with the same accuracy as it processes ten. This ability to scale on demand means you can launch ambitious promotions with confidence, knowing your operations can handle the success.

Manual processes have a nasty habit of hiding valuable information in messy spreadsheets and disconnected inboxes. It’s almost impossible to spot trends when you're buried in the details of one order at a time.

An automated system acts as a central hub for all your order data, turning it into a goldmine of insights you can actually use. You get a clean, real-time dashboard of your most important metrics.

- Top-selling products and what regions they're popular in.

- Inventory velocity, showing you exactly how fast different SKUs are flying off the shelves.

- Fulfillment efficiency, pinpointing any slowdowns in your pick-and-pack process.

This data empowers you to make smarter decisions about what to stock, where to market, and how to operate, fueling growth that lasts.

To put these benefits into perspective, let's compare the two approaches side-by-side.

The table below breaks down the real-world differences between sticking with manual methods and embracing automation. The contrast in operational outcomes is stark.

Metric Manual Processing Automated Processing Error Rate High (5-10% average) due to typos, data entry mistakes Extremely low (<1%), data is pulled directly from source Order Throughput Limited by staff hours and efficiency 24/7 processing, handles thousands of orders per hour Fulfillment Time Hours or days from order to warehouse floor Seconds or minutes from order to warehouse floor Scalability Poor; requires hiring more staff for sales spikes Excellent; scales instantly to handle any order volume Customer Comms Inconsistent, manual, and reactive Consistent, automatic, and proactive (confirmations, tracking) Data Visibility Poor; data is fragmented and hard to analyze Excellent; centralized real-time dashboard and reports Labor Costs High and scales directly with order volume Low; fixed software cost, reduces need for data entry staff

As you can see, the choice isn't just about efficiency—it's about building a more resilient, customer-focused, and data-driven business. Automation fundamentally changes what's possible for your operations.

While the automation we’ve discussed so far is fantastic, it’s mostly based on following a strict set of rules. The next chapter in automated order processing is about getting smarter. We're talking about systems that don't just follow instructions but think, predict, and adapt on their own.

We’re shifting from simple "if-then" logic to a world where our systems can anticipate problems and opportunities before they even happen. This is turning order management from a reactive, day-to-day chore into a powerful strategic advantage for any business willing to lean into the future.

The big leap forward is the move from basic automation to true operational autonomy. At the heart of this shift are two game-changing technologies: artificial intelligence (AI) and machine learning (ML). These aren't just buzzwords; they’re the engines that allow systems to analyze vast amounts of data, learn from past outcomes, and make decisions without a human needing to step in.

This new wave of technology goes far beyond just moving data between fields. It’s a powerful mix of AI, ML, robotic process automation (RPA), the Internet of Things (IoT), and even blockchain that's completely changing what’s possible. AI and ML are the brains of the operation, improving real-time decisions, while RPA bots are the hands, handling complex tasks with incredible speed. You can explore how these technologies revolutionize e-commerce to get a deeper sense of their impact.

One of the most exciting applications of AI is in demand forecasting. Historically, this meant looking at last year's sales and making an educated guess. AI completely flips that model on its head.

AI models sift through massive, real-time datasets that include not just your sales history but also current market trends, social media sentiment, competitor pricing, and even things like upcoming weather patterns.

Imagine your system spots a niche product style gaining traction on Instagram. It could then alert you to stock up before it becomes a mainstream trend. This puts you ahead of the curve, ready to meet the surge in demand instead of scrambling to catch up.

This kind of proactive inventory management helps businesses walk the fine line between frustrating stockouts and expensive overstock. Your inventory becomes a finely tuned asset, perfectly synced with what your customers actually want.

When we say robots, we’re not just talking about the physical ones in the warehouse. We’re also talking about software robots, specifically Robotic Process Automation (RPA), that manage complex digital work behind the scenes.

These aren't your grandfather’s data-entry scripts. Modern RPA bots can:

- Make rule-based decisions: If an order gets flagged for fraud, an RPA bot can check it against multiple data sources and decide whether to approve it or pass it to a human for a closer look.

- Manage complex communications: Bots can log into supplier portals to check inventory or confirm shipping dates, all without human intervention.

- Handle exceptions intelligently: If a shipping carrier reports a delay, the bot can immediately start looking for an alternative route or carrier to keep the order on track.

The Internet of Things (IoT) is the glue that connects the physical warehouse to the digital system. By embedding smart sensors into everything from shelves to shipping containers, you create a constant stream of real-time data about your operations.

Picture "smart shelves" that know when stock is low and automatically trigger a reorder request with your supplier. Or think about temperature sensors on a pallet of fresh produce that monitor conditions throughout transit, guaranteeing quality and flagging any problems the moment they occur. This level of visibility makes the entire supply chain transparent and instantly responsive.

Taking the leap to an automated system can feel like a huge undertaking, but it doesn't have to be. The trick is to break the process down into a clear, strategic roadmap. Think of it less like a dense technical manual and more like a game plan—a series of smart moves designed to build momentum and get you real results.

The journey starts not with new software, but with a hard look at where you are right now. Before you can improve a process, you have to know it inside and out.

First things first: you need to become an archaeologist of your own business. It's time to meticulously document every single touchpoint in your current manual order process. Who does what? Which systems are they using? How long does each step really take?

This exercise is incredibly revealing. It will expose the hidden cracks in your operation—the data entry bottlenecks, communication gaps, and repetitive tasks that are quietly draining your time and money. Pinpointing these specific pain points is the only way to know where automation will pack the biggest punch.

Once you have a crystal-clear map of your current workflow, you can define what a "win" actually looks like. Vague goals like "being more efficient" won't cut it. You need specific, measurable targets for your automated order processing system.

What are you trying to accomplish?

- Faster Shipping: "We will reduce our average time-to-ship from 48 hours to just 12 hours."

- Fewer Errors: "Our goal is to slash the order error rate from 3% to less than 0.5%."

- Lower Costs: "We aim to cut operational costs per order by 15% within six months."

These concrete objectives will be your North Star, guiding every decision you make, from the technology you choose to how you measure your return on investment.

Choosing your software is one of the most critical decisions you'll make on this journey. Not all platforms are built the same, and the right partner will feel like a natural extension of your team. When you're looking at different options, try to see past the flashy features and focus on what truly matters for your business in the long run.

Here's what to look for:

- Integration Power: How easily does it connect with your existing e-commerce platform, ERP, accounting software, and other tools you rely on?

- Scalability: Can the system handle the massive sales spikes you see during the holidays without breaking a sweat?

- Total Cost of Ownership: Make sure you understand the full financial picture, including subscription fees, implementation costs, and any potential hidden charges.

For automated order processing to be truly effective, a seamless connection with your entire tech stack is non-negotiable.

The role of AI in these systems is also exploding. The global market for AI in supply chain management is projected to grow at a staggering 38.8% CAGR, hitting an estimated $41.2 billion by 2030. Companies that have already jumped on board are seeing big wins, including a 15% reduction in logistics costs and a 65% improvement in service efficiency. You can discover more insights about these supply chain statistics to see just how much technology is shaping the industry.

Don't flip a switch and change everything overnight—that's a recipe for chaos. Instead, start small with a phased rollout. A pilot program acts as your safety net, allowing you to test the new system in a controlled environment with a limited number of orders.

This approach lets you identify and work out any kinks—whether it’s a faulty integration or a confusing user interface—before they can affect your entire customer base. Rigorous testing during this phase is the key to a stress-free full launch.

Finally, remember that launching your new system isn't the finish line. Your automation platform is a living, breathing part of your business that needs ongoing attention. The work doesn't stop once the system is live; in many ways, it's just beginning. This same mindset is crucial when you look to automate customer support, as both processes thrive on constant refinement.

Keep a close eye on your performance data, get feedback from your team, and always be on the lookout for new ways to make your workflows even better. Successful automated order processing isn't a one-and-done project—it's a commitment to continuous improvement.

Jumping into automated order processing is a fantastic move, but it's no silver bullet. I've seen too many businesses get excited, plug in some new software, and accidentally create a bigger mess than they started with. Knowing where others have stumbled is the absolute best way to make sure your own transition to automation is a win.

Getting this right means being honest about the traps that can completely derail an otherwise solid plan. The classic mistake? Focusing all your energy on the shiny new tech and forgetting about the people and processes that make it all run.

Let's walk through the most common pitfalls and, more importantly, how to sidestep them.

This is the big one. If your current manual process is a tangled mess of confusing steps and workarounds, slapping automation on top just makes the chaos happen faster. Automation is an amplifier; it will magnify whatever you feed it, good or bad.

Before you even think about a demo, take a hard look at your current workflow. Map it out from start to finish. Where are the bottlenecks? What steps are redundant? Simplify and clean up your process first. Only then should you bring in technology to supercharge that refined system.

Not all automation platforms are built the same. A frequent misstep is picking a tool that solves today’s puzzle but can’t grow with you. A system that doesn't play well with your other software or chokes during your busy season will become a huge liability, fast.

To dodge this bullet, look for solutions that offer:

- Robust Integrations: Make sure it connects smoothly with your e-commerce platform, accounting software, and warehouse management system. No exceptions.

- Scalability: Can it handle a 2x or 5x spike in orders during the holidays without breaking a sweat? It needs to.

- Flexibility: Your business has its own quirks. The tool must let you customize workflows and rules to match how you operate.

Think about where you'll be in two years, not just two months. A slightly more capable system now can save you from a very expensive and painful migration later.

An automation system is only as smart as the data it receives. If your product SKUs, inventory counts, or customer addresses are a minefield of typos and errors, you're just programming your system to make mistakes on your behalf. Bad data is a poison that guarantees automated failures.

This is a classic IT principle: "Garbage In, Garbage Out" (GIGO). It means that if you feed a system flawed information, you will get flawed results. The system will dutifully ship the wrong item or send a package to a non-existent street if that’s what the data tells it to do.

The fix is a serious commitment to data hygiene. Before you go live, audit your entire product catalog and customer database. Even better, get ahead of future problems when you automate data entry to ensure clean, accurate information from the very start.

Finally, never, ever forget the human element. You could have the most sophisticated automated order processing system on the planet, but if your team doesn't get it, doesn't trust it, or doesn't know how to use it, the project is dead on arrival. Failing to bring your people along for the ride is a recipe for resistance and misuse.

Involve your team from day one. Explain why you're making the change, focusing on how it will eliminate tedious tasks and make their jobs better—not how it will replace them. Provide thorough training, create easy-to-read guides, and be there to answer questions. A well-prepared team is your single greatest asset for a smooth and successful rollout.

Thinking about making the switch to automated order processing? It's a big step, and it's only natural to have some practical questions. We get it. Forget the high-level theory for a moment—let's get into the real-world concerns that pop up when you're on the verge of changing how your business runs.

We hear the same questions time and again from owners and managers just like you. Here are the straight answers to help you understand the nuts and bolts of what this change actually looks like.

This is usually the first question, and the good news is that automation is far more affordable than it used to be. Most modern platforms use a SaaS (Software as a Service) model. Think of it like a Netflix subscription for your business operations—you pay a predictable monthly or annual fee. These plans are typically tiered, so you only pay for what you need, whether that's based on your order volume or specific features.

Of course, a massive enterprise with one-of-a-kind needs could go the custom-built route, but that comes with a hefty upfront development cost. For almost everyone else, a scalable SaaS tool offers the perfect mix of power and predictable spending, without the huge capital investment.

That's a myth we need to bust right now. Years ago, this kind of tech was reserved for the corporate giants. Not anymore. Today's cloud-based solutions are built to scale with you, not just for you.

Many platforms have entry-level plans designed specifically for small businesses. You can start by automating the most critical tasks without breaking the bank. Then, as you grow from processing 50 orders a month to 50,000, you can just move up to the next plan. The whole point is to deliver value from the very beginning, no matter your size.

This one trips people up, but the distinction is pretty simple. It helps to think of an Order Management System (OMS) as your command center and the automation as the tireless worker carrying out your orders.

- An OMS is the dashboard. It’s where you get the bird's-eye view—tracking orders, managing inventory, and seeing everything in one place.

- Automated order processing is the action. It's the set of "if-then" rules that does the heavy lifting: verifying an order, routing it to the right warehouse, or printing a shipping label without anyone lifting a finger.

Think of it this way: The OMS gives you the information and control to make smart decisions. Automation is what turns those decisions into actions, instantly.

The timeline really hinges on how complex your current setup is. For a simple integration, like connecting a single Shopify store to an automation platform, you could be live in just a few weeks. That process usually involves linking your accounts, defining a few basic rules, and getting your team comfortable with the new system.

On the other hand, if you're a larger business integrating multiple sales channels, a custom ERP, and several warehouses, you should plan for a more involved project that could take several months. In those bigger scenarios, we always recommend a phased rollout. Start with a small pilot program to work out the kinks before going all in.

Ready to stop managing orders and start scaling your business? Spur uses powerful, actionable AI to automate your customer support and marketing communications across every channel. From answering FAQs instantly to updating orders and engaging customers 24/7, Spur frees your team to focus on growth. Launch in minutes with a 7-day free trial and see the difference for yourself.